Introduction to Industrial Heaters

Industrial heaters are essential equipment utilized in various commercial and industrial applications, primarily for heating processes, maintaining temperature, and ensuring optimal operational efficiency. In the context of the Philippines, the importance of industrial heaters cannot be overstated. With a rapidly evolving industrial sector, these units serve as critical components in manufacturing, food processing, and several other industries that require precise temperature control.

There are several types of industrial heaters available in the market, each designed to meet specific heating requirements. Among the common categories are electric heaters, gas-fired heaters, and infrared heaters. Electric industrial heaters are known for their efficiency and precise temperature management, making them ideal for applications where rapid heating is necessary. Gas-fired heaters, on the other hand, tend to be more economical for larger operations requiring substantial heat output. Infrared heaters provide immediate heat to objects and surfaces, benefiting industries that prioritize instant heating solutions.

In the Philippine industrial landscape, where various sectors such as agriculture, textiles, and manufacturing thrive, industrial heaters play a pivotal role. The geographical and climatic conditions in the Philippines necessitate the use of reliable heating solutions to maintain product quality and operational effectiveness. As industries seek to enhance productivity and ensure quality, investing in appropriate heating technology becomes increasingly significant. This guide aims to explore the diverse range of industrial heaters available, along with manufacturers and suppliers in the Philippines, highlighting their innovations and contributions to meet the rising demand for heating solutions.

Types of Industrial Heaters

In the Philippines, diverse industrial heaters are available to meet various heating requirements across numerous sectors. Among the most prominent categories of industrial heaters are electric heaters, gas heaters, oil heaters, and steam heaters, each serving specific applications while delivering unique benefits.

Electric heaters are widely utilized in industrial settings due to their efficiency and ease of operation. They convert electrical energy into heat, making them an ideal choice for environments where quick heating is necessary. Businesses often employ electric heaters for localized heating tasks or processes where precise temperature control is critical. Their compact design and low maintenance requirements further enhance their appeal in manufacturing and other sectors.

Gas heaters, on the other hand, are favored for their rapid heating capabilities and operational cost-effectiveness. Utilizing propane or natural gas, these heaters are particularly efficient for large-scale heating operations. In industrial applications, gas heaters are commonly used in drying processes and space heating, providing an economical and effective solution for substantial heating demands.

Oil heaters operate by heating oil, typically using an electric or gas burner as a heat source. The oil retains heat effectively, making these heaters suitable for prolonged operations. Industries such as manufacturing and processing often rely on oil heaters for continuous heating applications, as they provide steady and consistent temperatures over time.

Lastly, steam heaters utilize steam as a heating medium, offering efficient heat transfer for various industrial processes. Steam heaters are extensively employed in sectors like food processing, chemical manufacturing, and pharmaceuticals, where maintaining temperature stability is crucial. They are known for their capability to deliver uniform heating and are often integrated into systems requiring periodic heating cycles.

Choosing the appropriate industrial heater in the Philippines requires a thorough assessment of the specific heating needs, budget constraints, and operational requirements of a business. Each type of industrial heater provides unique advantages, making it essential to evaluate options carefully to ensure optimal performance and energy efficiency.

Key Industries Using Industrial Heaters in the Philippines

The use of industrial heaters is crucial in several key industries throughout the Philippines, each leveraging these heating solutions to enhance operational efficiency and product quality. Among these sectors, manufacturing, food processing, pharmaceuticals, and construction stand out as the primary consumers of industrial heating equipment.

In the manufacturing industry, industrial heaters play a vital role in various processes, such as metal treatment, plastic fabrication, and chemical production. These heaters ensure that production lines operate at optimal temperatures, thus enhancing productivity and preventing material defects. The versatility of industrial heaters also allows manufacturers to tailor their applications accordingly, addressing specific temperature and heating requirements unique to their production processes.

The food processing sector significantly benefits from industrial heaters, as they are essential for cooking, drying, and pasteurizing foods. Maintaining the correct temperature is critical for food safety and product consistency. In the Philippines, where diverse food products are processed, the use of reliable and efficient heating solutions enables companies to meet both local and international quality standards.

Pharmaceutical companies also rely on industrial heaters to maintain sterile environments and ensure precise temperature control during the production of medications and vaccines. The heaters facilitate processes like sterilization, excipient melting, and even the production of biopharmaceuticals. Thus, investing in quality industrial heaters is imperative for maintaining compliance with stringent health regulations.

Finally, the construction industry utilizes industrial heaters for applications such as curing concrete and managing temperature during various construction processes. By employing the right heating solutions, construction firms in the Philippines can mitigate the effects of environmental conditions and ensure the integrity of the materials used.

These key industries illustrate how industrial heaters are integral to various operations, improving quality and efficiency. As businesses in the Philippines continue to evolve, the ongoing demand for industrial heaters remains evident, highlighting their essential role in modern industrial applications.

Factors to Consider When Choosing an Industrial Heater

When selecting an industrial heater in the Philippines, several critical factors must be taken into account to ensure that the chosen equipment meets the specific requirements of the application. First and foremost is the heating capacity. It is essential to assess the size of the area that needs heating and the desired temperature increase. Choosing a heater with the appropriate capacity is vital; a unit that is too small will struggle to achieve the required temperature, while one that is too large can lead to energy wastage and increased operational costs.

Another important consideration is energy efficiency. In the current economic climate, where energy costs are a significant consideration for businesses, selecting a heater with high energy efficiency ratings can lead to substantial savings over time. It is wise to look for models that utilize advanced technology such as thermal insulation and variable speed controls, which can enhance efficiency further.

Installation requirements also play a crucial role in the decision-making process. Some industrial heaters may require complex setups or specific environmental conditions. Understanding the installation process and requirements helps to avoid potential challenges and additional costs after purchase. Furthermore, it is essential to consider the upfront cost and the long-term maintenance needs. An initial lower-priced unit may come with higher ongoing maintenance costs or less durability than a slightly more expensive, high-quality alternative.

Ultimately, businesses should engage with suppliers to discuss these factors in-depth. Selecting the right industrial heater not only ensures operational efficiency but also significantly affects the overall productivity of their operations in the Philippines.

Leading Manufacturers of Industrial Heaters in the Philippines

The industrial heater market in the Philippines comprises several reputable manufacturers renowned for their high-quality products and innovative solutions. These companies cater to various sectors, offering a wide range of industrial heaters that meet diverse operational needs.

One of the foremost manufacturers is Calorific, which specializes in high-performance industrial heaters suitable for various applications, including petrochemical and food processing industries. With a proven track record for reliability and efficiency, Calorific has established a solid market presence in the Philippines. Their heaters are designed with advanced technology, ensuring optimal thermal efficiency while minimizing energy consumption.

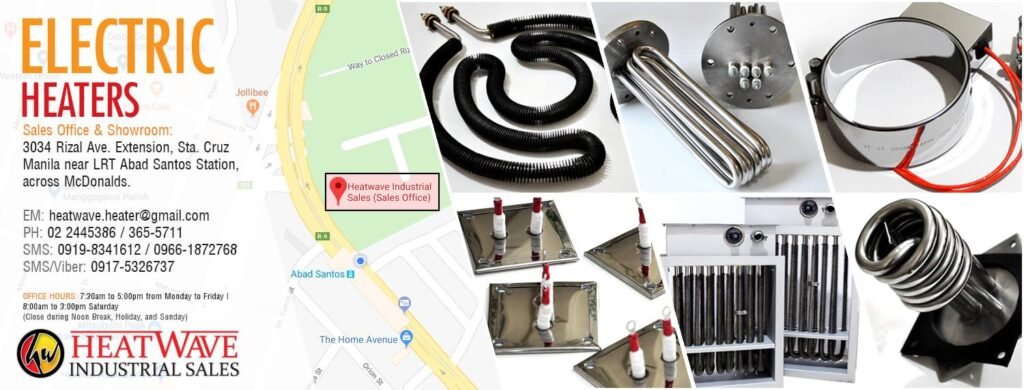

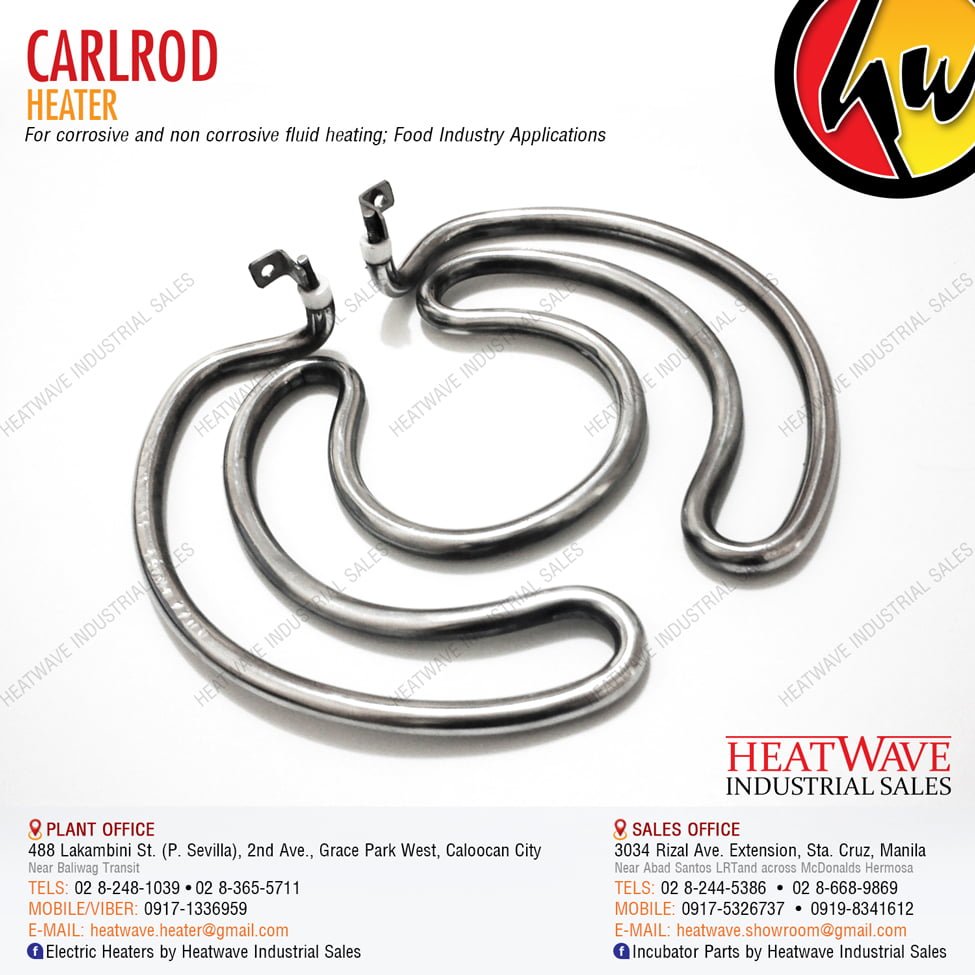

Another significant player in the Philippine market is HeatWave Technologies. Known for their custom industrial heater solutions, HeatWave offers a variety of products, from electric immersion heaters to heat exchangers. Their commitment to innovation and customer service has garnered them a strong reputation in the industry. They emphasize energy efficiency in their designs, allowing businesses to reduce operational costs while maintaining effective heating solutions.

Associated Manufacturing Corporation is also a key entrant in the industrial heater market in the Philippines. They provide a wide selection of industrial heater types, including standard and bespoke models tailored to specific applications. Recognized for their durability and performance, AMC heaters are built to withstand the tough conditions typically found in industrial environments.

Additionally, ThermoTech International has gained prominence with its adept integration of technology and functionality. Their products emphasize advanced safety features, making them a preferred choice for sectors that prioritize operational safety. The company is committed to sustainable practices, offering eco-friendly options in their line of industrial heaters.

These leading manufacturers demonstrate that the industrial heater landscape in the Philippines is both diverse and dynamic, featuring products that align with the varying demands of different industries. Through constant innovation and a focus on quality, they continue to strengthen their positions in the competitive market.

Reputable Suppliers of Industrial Heaters

When it comes to acquiring industrial heaters in the Philippines, the importance of selecting reputable suppliers cannot be overstated. A reliable supplier is paramount not only for the immediate provision of equipment but also for the ongoing support and reliability of the products. Choosing a supplier with a solid reputation ensures that the industrial heater you invest in will be of high quality, suitable for your specific applications, and supported through its lifecycle.

Several well-known suppliers in the Philippines have established themselves as leaders in the industry, offering a combination of quality products and excellent customer service. One such supplier is XXX Industrial Supplies, renowned for their extensive range of industrial heaters which include electric, gas, and infrared options. Their long-standing presence in the market, combined with a knowledgeable team, guarantees that customers receive expert advice tailored to their needs.

Another reputable player is YYY Heating Solutions. Known for their customer-centric approach, they provide end-to-end solutions from consultation to after-sales support. They also offer customized industrial heating systems to meet unique operational requirements, ensuring that customers do not compromise on efficiency.

Consideration should also be given to ZZZ Thermal Technologies, which is noted for their commitment to innovation and sustainability. They not only provide traditional industrial heaters but also focus on energy-efficient options that help reduce operational costs over time. Their products come with warranties and a robust support system, enabling companies to maintain uninterrupted operations.

Partnering with reputable suppliers for industrial heaters in the Philippines not only facilitates peace of mind but also significantly contributes to the overall efficiency of industrial operations. Ensuring that your supplier has a proven track record in delivery, support services, and warranty offerings can be a decisive factor in your long-term success.

Cost Considerations for Industrial Heaters

Determining the cost of industrial heaters in the Philippines requires an in-depth analysis that encompasses various financial aspects, including initial costs, operational expenses, and long-term savings. The initial investment in an industrial heater can vary significantly based on the model, capacity, and technology employed. While comparing prices, it is crucial to consider the specifications of the heater that match the unique industrial needs.

Operational expenses play a vital role in the overall cost considerations of industrial heaters. These expenses primarily consist of energy costs, maintenance, and replacement parts. Energy consumption varies based on the heater’s efficiency, and selecting a high-efficiency model can lead to reduced operational costs over time. Regular maintenance not only extends the lifespan of the equipment but also ensures optimal performance, which is essential for minimizing energy expenses. Thus, when evaluating industrial heater options, it is wise to factor in both the anticipated maintenance costs and the efficiency ratings of the units.

Financial strategies such as leasing or financing options may also ease the burden of initial costs. Many suppliers and manufacturers within the Philippines offer flexible payment plans, allowing businesses to manage their budgets more effectively while still investing in the technology their operations require. It is essential for organizations to assess their long-term financial outlook when selecting an industrial heater, as up-front expenditures can be offset by future savings on energy bills and reduced downtimes associated with inefficient equipment.

In conclusion, when calculating the total cost of ownership for industrial heaters in the Philippines, organizations must take into account not only the initial purchase price but also ongoing operational costs, maintenance needs, and potential financing solutions. An informed decision in this regard can lead to significant long-term financial advantages, promoting both operational efficiency and sustainability.

Maintenance and Safety Tips for Industrial Heaters

Maintaining industrial heaters in the Philippines is crucial to ensure optimal performance and longevity. Regular maintenance not only extends the lifespan of the equipment but also enhances its efficiency, ultimately leading to cost savings. To begin with, it is advisable to conduct routine inspections. Look for any signs of wear and tear, particularly on heating elements, electrical connections, and control panels. A scheduled maintenance plan should be established, including checks for any unusual noises, leaks, or the accumulation of dirt and debris.

It’s important to clean the industrial heater regularly to prevent dust and residue build-up, which could hinder its effectiveness. Use appropriate cleaning agents that are compatible with the materials of the heater, ensuring no damage occurs during the cleaning process. Additionally, verify that all safety devices, such as thermal cutoffs and pressure relief valves, are functioning correctly. This proactive approach mitigates the risk of potential failures and accidents.

Safety cannot be overstated when it comes to the operation of industrial heaters. Operators should be trained adequately on the specific heater they are using, as each model may have different requirements and safety protocols. Employing protective gear — such as gloves and safety goggles — is essential when handling this equipment. Furthermore, ensure that the installation site has proper ventilation to prevent the build-up of harmful gases that could result from heater operation.

Emergency procedures should also be established and communicated to all personnel working in proximity to the industrial heater. Regular safety drills can prepare the team for unforeseen circumstances. In conclusion, the combination of diligent maintenance and adherence to safety protocols will ensure the efficient operation of industrial heaters in the Philippines, safeguarding both personnel and investment in equipment.

Conclusion: The Future of Industrial Heaters in the Philippines

The landscape of industrial heaters in the Philippines is undergoing significant transformation, driven by advancements in technology, a growing emphasis on sustainability, and the persistent demand for efficient heating solutions. As industries continue to evolve, the role of industrial heaters becomes increasingly vital in ensuring operational efficiency and reducing energy consumption.

Technological advancements have led to the development of more sophisticated industrial heater systems, incorporating smart technology and automation. These innovations not only enhance the performance of heating systems but also facilitate real-time monitoring and control, enabling businesses to optimize their energy use. The integration of IoT devices allows for predictive maintenance, which can reduce downtime and extend the lifespan of equipment.

Moreover, sustainability is becoming a key focus for many industrial sectors in the Philippines. Companies are recognizing the importance of adopting environmentally friendly practices. This has resulted in a push towards industrial heaters that utilize renewable energy sources, such as solar or bioenergy. The movement towards greener heating options not only reduces the carbon footprint but also aligns with global trends towards sustainability, benefiting both the environment and businesses in the long run.

Despite the ongoing advancements, the demand for efficient industrial heaters remains strong. As industries become more competitive and cost-sensitive, the need for reliable heating solutions that reduce operational costs will only grow. The Philippine market is poised for further development in this sector, with numerous manufacturers and suppliers ready to adapt to the evolving needs of industries. As the future unfolds, it is clear that industrial heaters will play a crucial role in shaping the productivity and sustainability of the industrial landscape in the Philippines.